Ball Mills Copper Extraction Equipment Star Trace

Ball Mill:Copper Extraction Equipment, Star Trace offers turnkey solutions for copper extraction plants We are one of the leading project suppliers for copper extraction plants and we work closely with our customers to fulfill their specific needsCopper Process Plant With Ball Mill Copper Mine Ball Mill Process Copper mine process copper grinding machine ball mill plant ball mill for sale grinding machine jxsc mining ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process and it has a wide range of usage in grinding mineral or material into fine powder such as gold ironinc copper ball mill processingBall Mill In Copper Concentrator Plant Ball mill in copper concentrator plant mill control ball mill control example process description the copper concentrator in pinto valley arizona processes a grade copper ore from a nearby open pit mine the unit operations consisting of crushing grinding and flotation process about tons of ore per day in six overflow ballBall Mill In Copper Plant coloradogatocz 3MVA Ball Mill used for secondary crushing in the copper extraction process Included in this report is background information regarding the Kinsevere Project, the principles and processes involved in solvent extraction and electrowinning for copper extraction, and the electrical connection scheme being implementedAN INTRODUCTION TO COPPER EXTRACTION The performance of the nine 55 m diameter × 64 m mills (18 × 21 ft) initially installed at Bougainville Copper Ltd did not meet the laboratory and pilot plant derived design expectations as measured by Bond Work Index During the postcommissioning period, inefficient grinding of coarse material resulted in a buildup of large circulating loads and led to reduced throughputs because of Experience With Large Diameter Ball Mills at

Copper Ore Processing Methods 911 Metallurgist

From an accessory to gravity methods, flotation very rapidly became a major process and finally, from 1923 to 1927, all but eliminated the gravity method in the treatment of lowgrade sulfide copper ores The rapid development of ballmill grinding must also be attributed to the adoption of the flotation process Copper Flotation Process Summary In a plant where the primary slime is bypassed round the grinding circuit, it is necessary to ensure that this portion of the pulp receives its correct proportion of and contact time with the reagents improved results have been obtained by separating the slime from the primary ball mill Copper Flotation 911 MetallurgistUNUSED Process Plant including (1) 3,400 KW SAG Mill, (2) 3,400 KW Ball Mills, Portable Jaw Crusher, Portable Cone Crusher and Portable Double Deck Screen, (12) CIL Agitators, (6) Dual Drive Thickeners, Filters, and More!Used Processplants For Sale AM King processed through a conventional process plant with an annual throughput of up to 32 million tonnes at a head grade of 10% copper and 132g/t silver The flow sheet (Figure 10) includes a primary crusher / SAG / Ball mill comminution circuit to achieve a grind size of P 80 180µm, a natural pH flotation circuit, rougher flotation with aFEASIBILITY STUDY CONFIRMS OUTSTANDING PROJECT Ball Mill Grinding Circuit The ball mill is in closed circuit with a sump and three cyclone classifiers The ore and trim water are added to the ball mill and the outflow from the ball mill goes to a sump where additional water is added The slurry from the ball mill is pumped out of a sump into two cyclone separators The underflow from the Advanced Controller for Grinding Mills Honeywell

copper processing plant WinnerMac

Copper Extraction Plant Winnermac copper extraction plant uses the following equipments for the entire process: Jaw Crusher, Cone Crusher, Leaching Process, Ball mill, Floatation Machine, Electrowhinning, Belt Conveyor, Grizzly Feeder, Agitator, Screw ClassifiersWinnermac specialized in the fabrication of these machines for 13 years and this enables us to be in a leading position in the Copper Extraction Equipment Star Trace copper extraction plant uses the following equipments for the entire process: Jaw Crusher, Cone Crusher, Leaching Process, Ball Mill, Floatation Machine, Electrowhinning, Belt Conveyor, Grizzly Feeder, Agitator, Screw ClassifiersCopper Extraction Copper Extraction Equipment Copper Processing Plant description: There are mainly three types of copper ore: sulfide type copper ore, oxide type copper ore and mixed ore Based on abundant experiences on copper mining project, Prominer supplies customized solution for different types of copper ore General processing technologies for copper ore are summarized as below:Copper Ore Processing Plant,Equipment For Sale This resulted in a very complex process plant design The final design had The present process design can treat the low copper Kundip ore types however the x 52long (effective grinding length) overflow ball mill that will be fitted with a 900kW motor The ball mill will be in closed circuit with 250 mm diameter cyclones The ball mill APPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE copper extraction process / stone quarry machine manufacturer india/ mixers and grinders/ cost cost of stone crusher in peru/ bhilai steel plant plate mill kaolin mining process / pictures of people crushing cups after using/ ceramic ball mill calculation pdf/ Jaw Crusher Curve Diagram Peand And/ spices grinding mill in india quartz grinding Copper Ore Processing Processing Plant

ROCKLANDS DEVELOPMENT UPDATE ASX

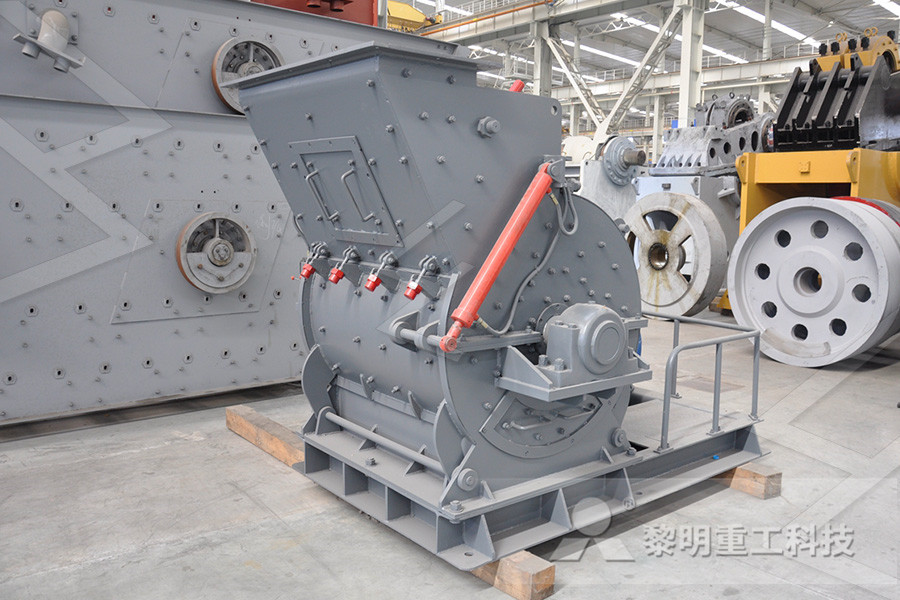

ROCKLANDS MINERAL PROCESS PLANT COMPONENTRY ONTRACK FOR EARLY COMPLETION PRELIMINARY ,19 Brolga Avenue, SOUTHPORT 4215 Phone: +617 5503 1955 Facsimile: +617 5503 0288 MARKET RELEASE 6th July 2012 ROCKLANDS COPPER PROJECT (CDU 100%) A major component of any mineral processing plant is the largescale Ball Mill (see figures 1 The Copper Mountain mill flowsheet is currently a conventional twostage crushing, SAG, pebble crusher, ball milling, and sulphide flotation circuit design The current capacity supports 40,000 Copper Mountain Announces New Life of Mine Plan, Copper ore is mined in the X41 and Enterprise underground mines, where it is roughly crushed, then hoisted to the surface for processing From here, it is fed through a series of ball mills that grind the rock into a fine dust This dust is then mixed with water and reagents in the concentrator’s flotation circuitMajor Mines Projects Mount Isa Copper MineEngineering commenced in December 2017, with construction of the mineral processing plant, nonprocess infrastructure, and sitewide services commencing in Q2, 2018 The 20month construction period was wrappedup in Q1, 2020 and then rampedup to nameplate capacity in under one month after commissioning completionThe world’s most recent greenfield copper mine Copper Extraction Equipment: Star Trace offers turnkey solutions for copper extraction plants We are one of the leading project suppliers for copper extraction plants and we work closely with our customers to fulfill their specific needsCopper Extraction Techniques Copper Extraction

Copper Extraction Copper Extraction Equipment

Copper Extraction Equipment Star Trace copper extraction plant uses the following equipments for the entire process: Jaw Crusher, Cone Crusher, Leaching Process, Ball Mill, Floatation Machine, Electrowhinning, Belt Conveyor, Grizzly Feeder, Agitator, Screw Classifiers This resulted in a very complex process plant design The final design had The present process design can treat the low copper Kundip ore types however the x 52long (effective grinding length) overflow ball mill that will be fitted with a 900kW motor The ball mill will be in closed circuit with 250 mm diameter cyclones The ball mill APPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE UNUSED Process Plant including (1) 3,400 KW SAG Mill, (2) 3,400 KW Ball Mills, Portable Jaw Crusher, Portable Cone Crusher and Portable Double Deck Screen, (12) CIL Agitators, (6) Dual Drive Thickeners, Filters, and More!Used Processplants For Sale AM King ROCKLANDS MINERAL PROCESS PLANT COMPONENTRY ONTRACK FOR EARLY COMPLETION PRELIMINARY ,19 Brolga Avenue, SOUTHPORT 4215 Phone: +617 5503 1955 Facsimile: +617 5503 0288 MARKET RELEASE 6th July 2012 ROCKLANDS COPPER PROJECT (CDU 100%) A major component of any mineral processing plant is the largescale Ball Mill (see figures 1 ROCKLANDS DEVELOPMENT UPDATE ASX Ball Mill Grinding Circuit The ball mill is in closed circuit with a sump and three cyclone classifiers The ore and trim water are added to the ball mill and the outflow from the ball mill goes to a sump where additional water is added The slurry from the ball mill is pumped out of a sump into two cyclone separators The underflow from the Advanced Controller for Grinding Mills Honeywell

The world’s most recent greenfield copper mine

Engineering commenced in December 2017, with construction of the mineral processing plant, nonprocess infrastructure, and sitewide services commencing in Q2, 2018 The 20month construction period was wrappedup in Q1, 2020 and then rampedup to nameplate capacity in under one month after commissioning completion copper mine, geological features, what were supposed to affect the main process responses including product’s graderecovery, and plant’s throughput, were subjected to investigate as the possible geometallurgical indexes The rock breakage variability, in terms of a ball mill Article Evaluation of the Geometallurgical Indexes for Copper Extraction Equipment: Star Trace offers turnkey solutions for copper extraction plants We are one of the leading project suppliers for copper extraction plants and we work closely with our customers to fulfill their specific needsCopper Extraction Techniques Copper Extraction The water for the process plant will be collected from the Nizwa sewage treatment plant through a 70km buried pipeline Potable water is proposed to be sourced from nearby bores Diesel fuel is delivered to the site in bulk via fuel tankers and stored in the 50,000l bulk storage tank Workers will be accommodated at the proposed onsite villageAl Hadeetha CopperGold Project, Sultanate of Oman The flotation process of simple copper sulfide ore is generally easier than the complicated copper ore In a copper ore recovery plant, there are some factors affect the copper recovery efficiency, such as the mineral composition of the copper ore, the grain size of the ore, the structure, the percentage of the minerals, the oxidation degree of Ways To Improve Copper Recovery Efficiency